How to Measure lnverter Output Voltage

Taking voltage measurements around drives (frequency drives or inverters if you prefer) requires the right test equipment and some attention to detail. You will be working with high voltage and high-frequency switching waveforms that are not pure sine waves.

Digital voltmeters don't usually produce reliable readings for these waveforms since they are not purely sinusodial. And it is also risky to connect high voltage signals to oscilloscopes, so with these limitation in mind there is still a fairly easy method to measure inverter output voltage.

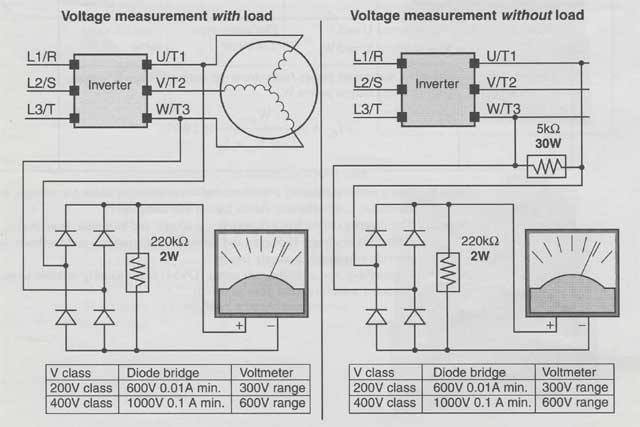

Since the inverter output semiconductors will most likely have some leakage, taking no-load measurements will produce misleading results.

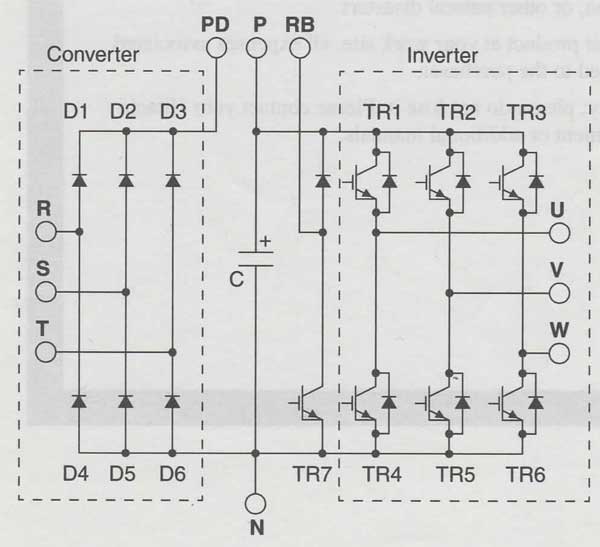

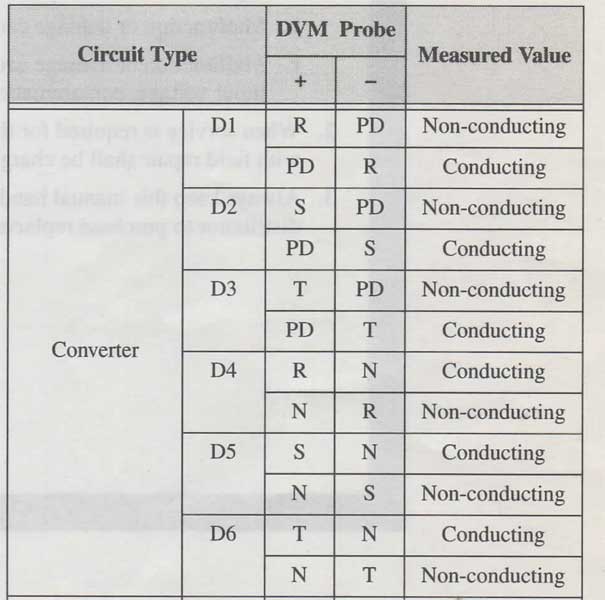

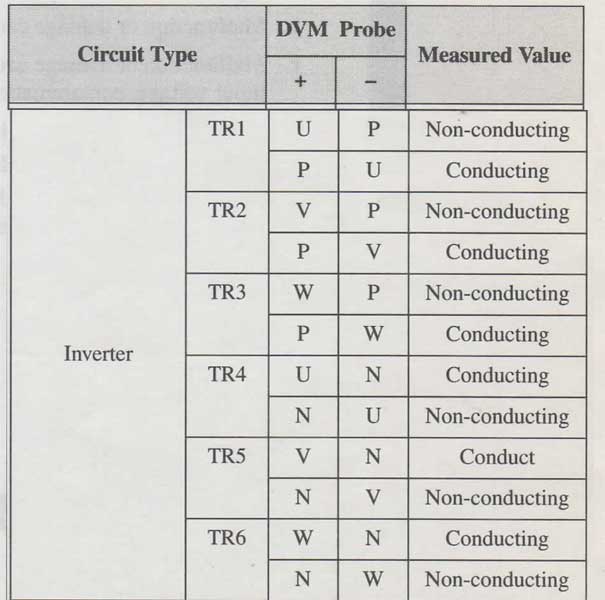

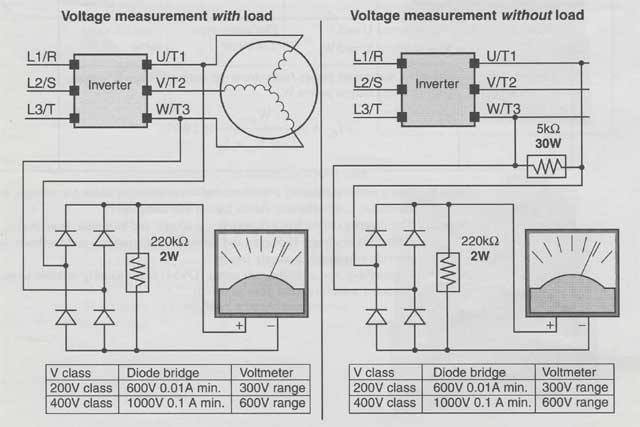

So, you will need to assemble a circuit like the ones here to measure voltage when performing drive maintenance or troubleshooting. This procedure is adapted from one presented an old Hitachi drive manual.

The testing circuits are assembled using common diodes and resistors.

You must use caution not to touch wiring or output terminals when working with the drive/inverter and taking these measurements.

Be sure to place the homemade testing circuits in an insulated housing before using them to avoid short circuiting or electrocution of the technician.

Taking voltage measurements around drives (frequency drives or inverters if you prefer) requires the right test equipment and some attention to detail. You will be working with high voltage and high-frequency switching waveforms that are not pure sine waves.

Digital voltmeters don't usually produce reliable readings for these waveforms since they are not purely sinusodial. And it is also risky to connect high voltage signals to oscilloscopes, so with these limitation in mind there is still a fairly easy method to measure inverter output voltage.

Since the inverter output semiconductors will most likely have some leakage, taking no-load measurements will produce misleading results.

So, you will need to assemble a circuit like the ones here to measure voltage when performing drive maintenance or troubleshooting. This procedure is adapted from one presented an old Hitachi drive manual.

The testing circuits are assembled using common diodes and resistors.

You must use caution not to touch wiring or output terminals when working with the drive/inverter and taking these measurements.

Be sure to place the homemade testing circuits in an insulated housing before using them to avoid short circuiting or electrocution of the technician.