Durant SERIES 1000 Trouble Shooting

If the Series 1000 Electronic Control does not perform satisfactorily the connections at the rear terminals should be checked first. If no loose wires or wiring errors are found remove all wires from the rear terminals and proceed through the following steps.

If the Control fails to function in any of the steps return it to Durant Digital Instruments, 901 S. 12th St., Watertown, Wi. 53094, Attn: Repair Dept. for repair with a letter describing the malfunction.

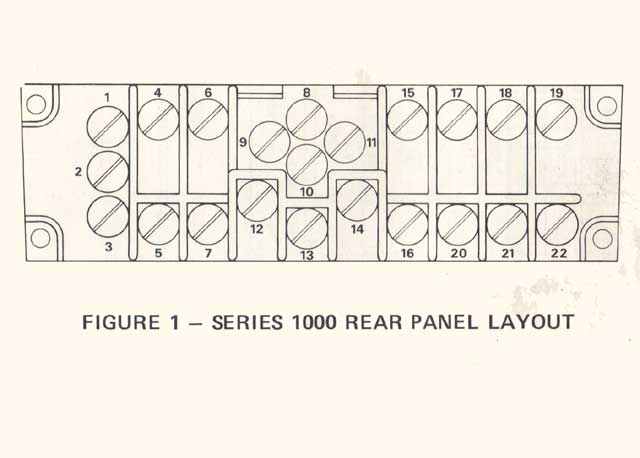

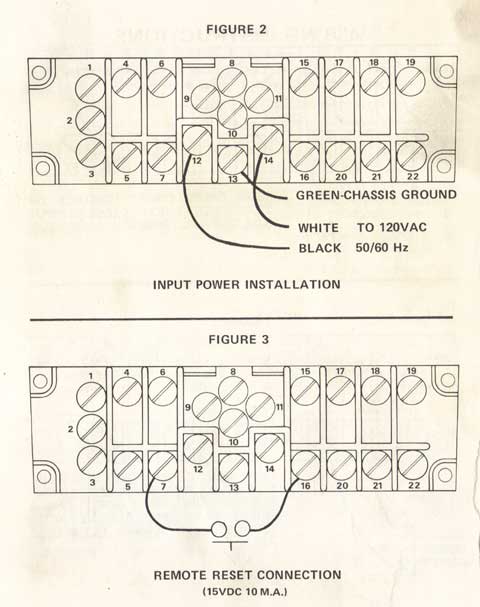

POWER INPUT:

Connect 120V.A.C. to terminals 12 and 14. The pilot light should be lit.

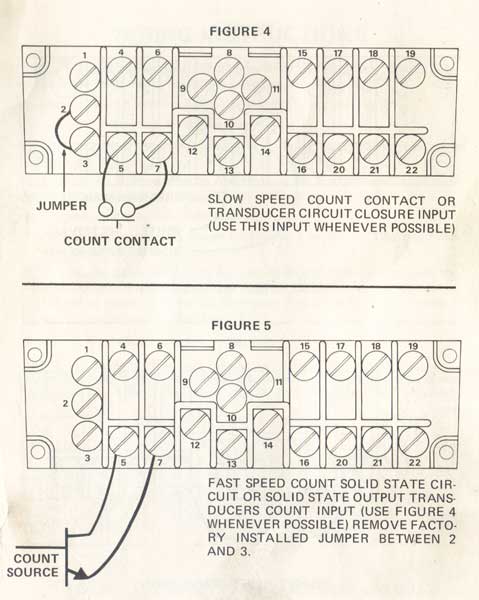

COUNT:

Make a momentary connection between terminals 5 and 7. While the connection is made the pilot light should be noticeably dimmer. Make a connection with a short piece of wire between terminals 2 and 3 and repeat the count test between terminals 5 and 7, the pilot light should change intensity. Retain the connection between terminals 2 and 3.

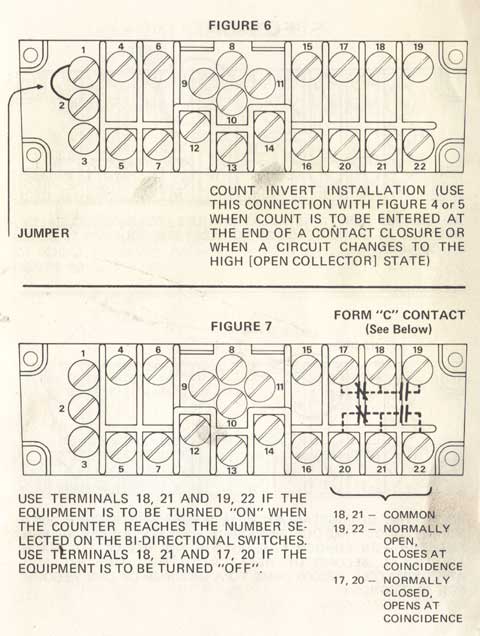

PREDETERMINED:

Set the Predetermined Setting at 0005. Interrupt the 120 V power to the control for a short time (about 2 seconds). Make a momentary connection between terminals 5 and 7 at least 5 times. You should hear the output relay actuate.

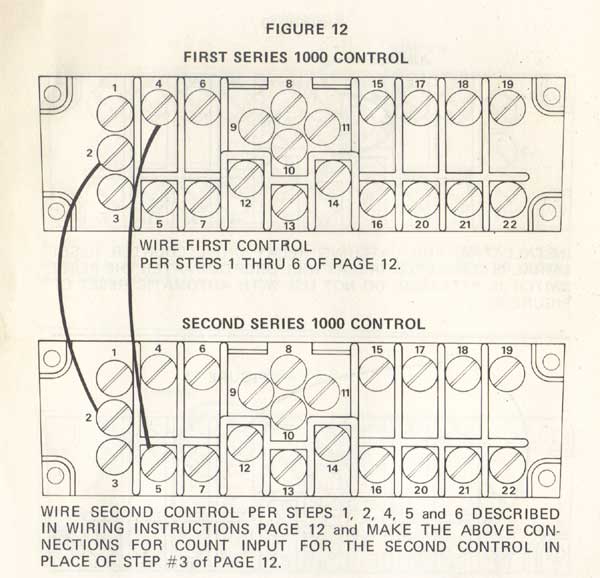

RELAY TIME OUT:

With the output relay actuated from the predetermined test make a connection between terminals 8 and 9. You should hear the output relay release.

UNLATCH:

With the output relay actuated from the predetermined test make a momentary connection between terminals 7 and 15. You should hear the output relay release.

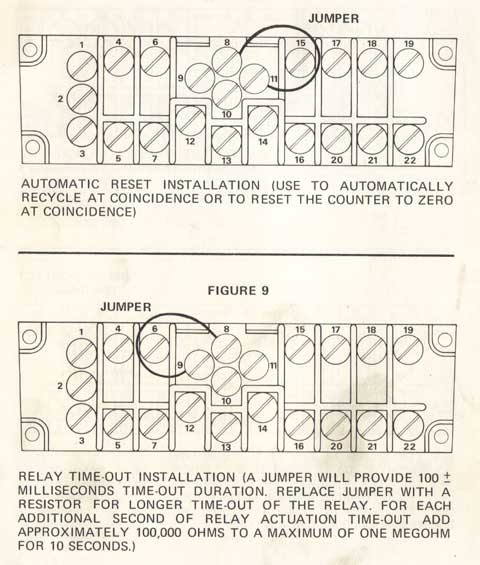

LATCH UNTIL RESET COMPLETE (LURC):

Make a connection between terminals 8 and 10 and actuate the output relay by performing the predetermined test. You should hear the output relay release when you release the reset switch after depressing it.

AUTO RECYCLE:

Make a connection between terminals 8, 9, and 11. Set the PredeÂtermined Setting at 0005, interrupt the 120 V power for a short time and make repeated momentary connections between terminals 5 and 7. You should hear the output relay actuate and release every 5 counts.

If the Series 1000 Electronic Control does not perform satisfactorily the connections at the rear terminals should be checked first. If no loose wires or wiring errors are found remove all wires from the rear terminals and proceed through the following steps.

If the Control fails to function in any of the steps return it to Durant Digital Instruments, 901 S. 12th St., Watertown, Wi. 53094, Attn: Repair Dept. for repair with a letter describing the malfunction.

POWER INPUT:

Connect 120V.A.C. to terminals 12 and 14. The pilot light should be lit.

COUNT:

Make a momentary connection between terminals 5 and 7. While the connection is made the pilot light should be noticeably dimmer. Make a connection with a short piece of wire between terminals 2 and 3 and repeat the count test between terminals 5 and 7, the pilot light should change intensity. Retain the connection between terminals 2 and 3.

PREDETERMINED:

Set the Predetermined Setting at 0005. Interrupt the 120 V power to the control for a short time (about 2 seconds). Make a momentary connection between terminals 5 and 7 at least 5 times. You should hear the output relay actuate.

RELAY TIME OUT:

With the output relay actuated from the predetermined test make a connection between terminals 8 and 9. You should hear the output relay release.

UNLATCH:

With the output relay actuated from the predetermined test make a momentary connection between terminals 7 and 15. You should hear the output relay release.

LATCH UNTIL RESET COMPLETE (LURC):

Make a connection between terminals 8 and 10 and actuate the output relay by performing the predetermined test. You should hear the output relay release when you release the reset switch after depressing it.

AUTO RECYCLE:

Make a connection between terminals 8, 9, and 11. Set the PredeÂtermined Setting at 0005, interrupt the 120 V power for a short time and make repeated momentary connections between terminals 5 and 7. You should hear the output relay actuate and release every 5 counts.